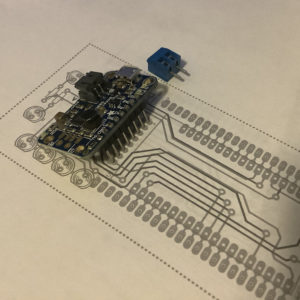

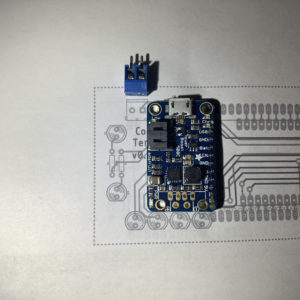

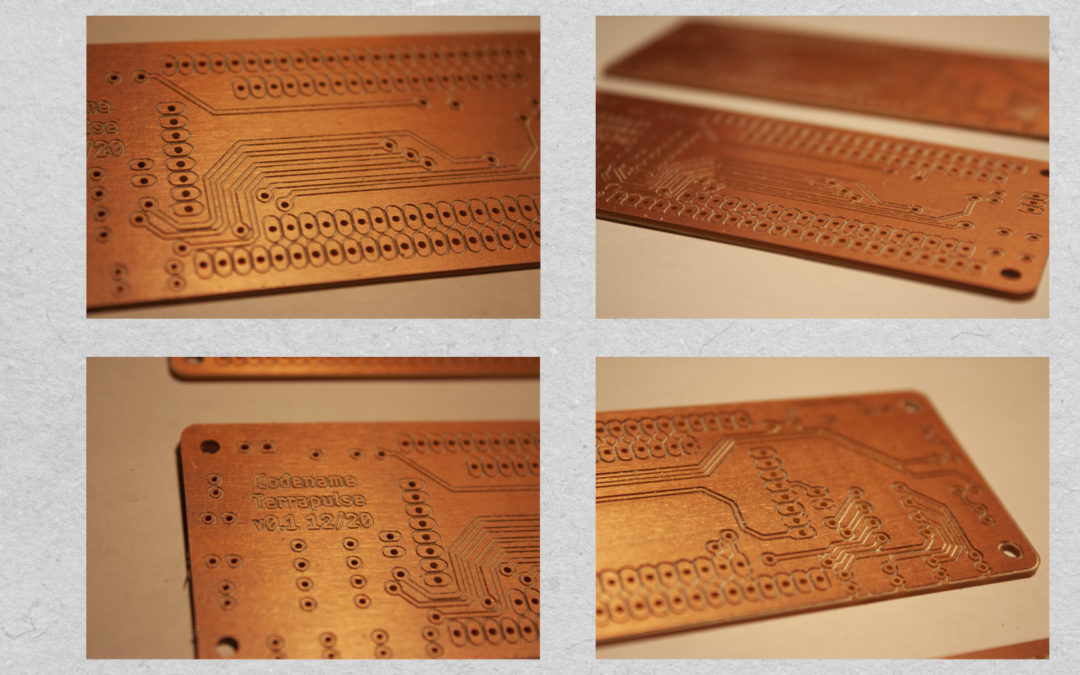

Tech Log #034: Milling v0.1 sensor node

- Paper test 1

- Paper test 2 after some adjustments

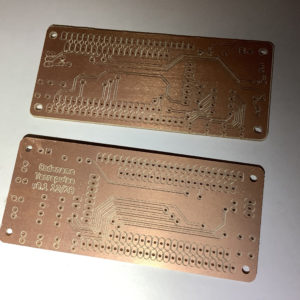

- Boards milled

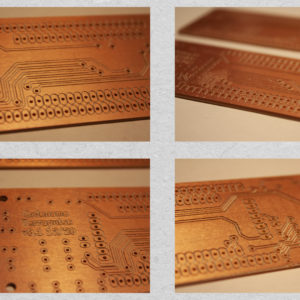

- Closeup of boards

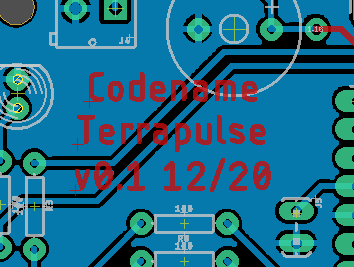

Tech Log #033: Circuit board v0.1 sensor node

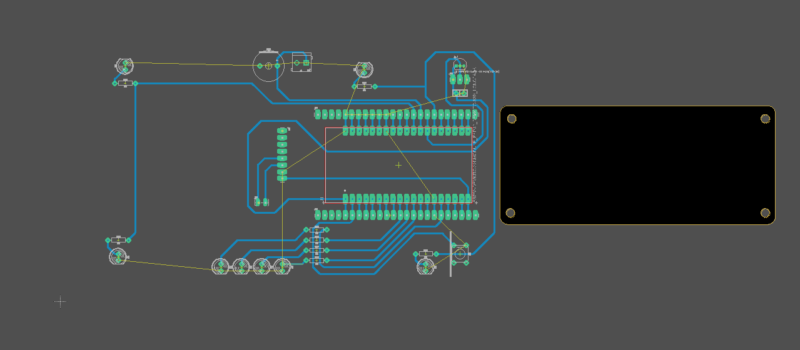

Board routing is done! Needed to do two iterations on it. The first iteration was routed without using the right dimensions on the outline. Oops. With the proper outline imported, everything needed to be placed closer together. Lesson learned: always import the proper outline (or close to it) as the first step. Alright, so the routing was completed fine. It is a 2 layer board with a copper pour on the back of the board. Tolerances for design for fabrication are 20 mils tracewidth, ample spacing at 10+ mils, and using longpads whenever possible. Vias are large like pads, so they can have a wire pass through them during the assembly stage. Next up is milling the board!

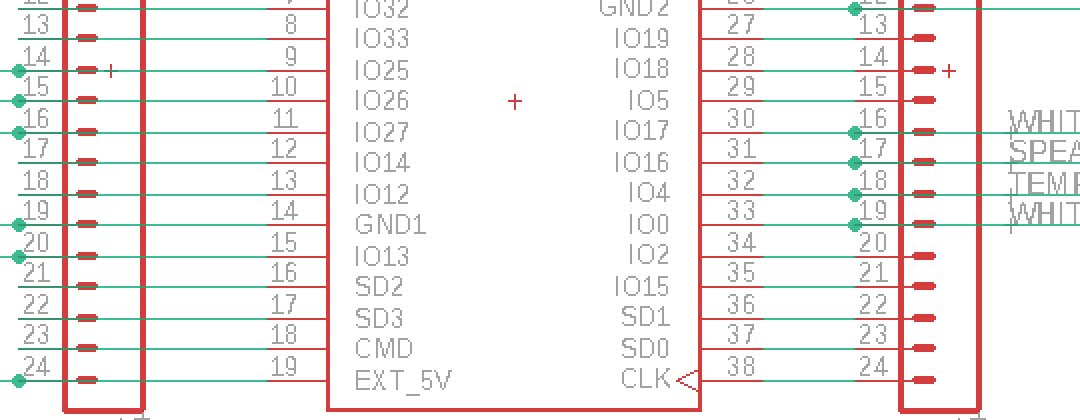

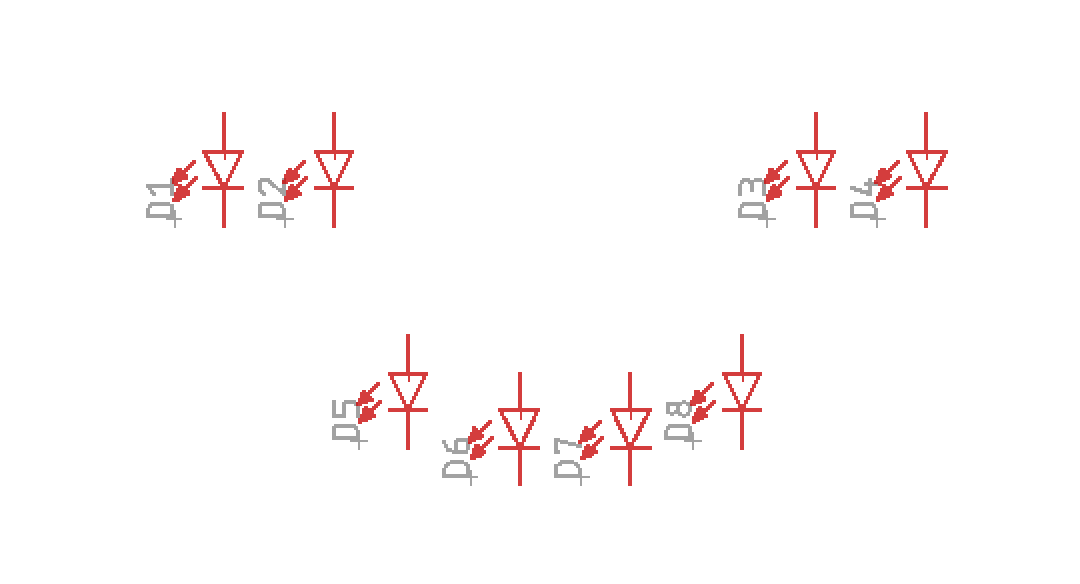

Tech Log #032: Schematic v0.1 sensor node

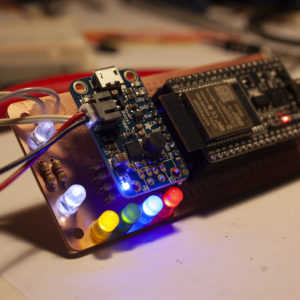

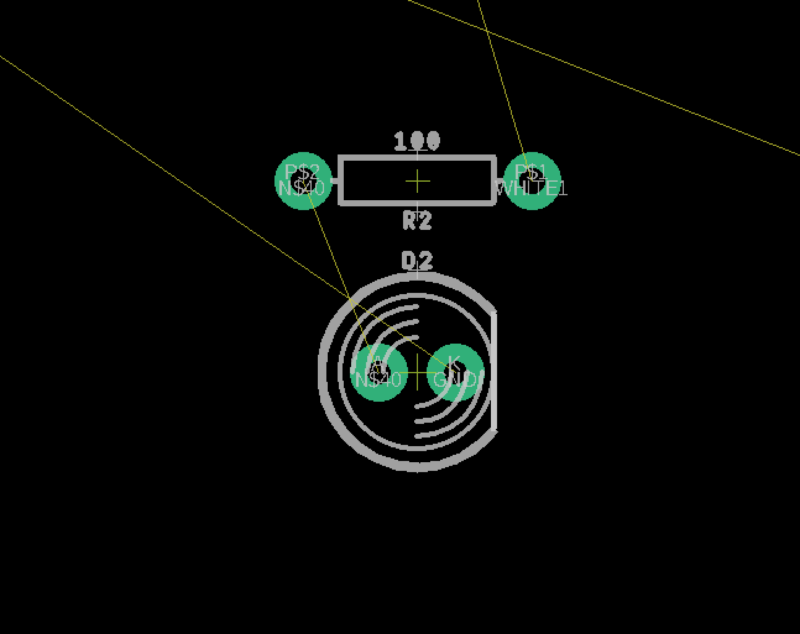

Schematic done for v0.1 of the sensor node! This is the most simplest design possible, with the barebones minimum. An ESP32 breakout, with headers to each side just in case, a reset switch, 6 LEDs, temperature sensor, speaker, and power boost board. All components are through hole at this moment in time. Pretty smooth sailing on this. Next step is to route the circuit board.

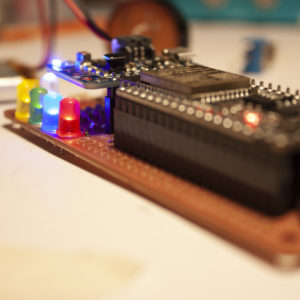

Tech Log #031: Basic functionality code, onto schematic

Basic code for the node to test input output functionality works. Two LEDs had to change pins as they were input only. PWM on ESP32 for LEDs is different than with the Arduino boards, that was interesting to learn about. Temperature sensor works, and analog input is 12 bit, so from 0 to 4095. Schematic is started. Next step is to complete the schematic, then board layout, and get the proper board outline with mounting holes into the design.